Food waste depackaging and separation equipment plays a significant role in managing and reducing waste, particularly in the food industry. This equipment is designed to separate packaging materials from the organic contents, allowing for more efficient recycling and disposal processes. The following is an in-depth analysis of how these machines work.

According to the Food and Agriculture Organization, about one-third of all food produced globally is wasted each year, highlighting the urgent need for effective food waste management. This article delves into the technology behind food waste depackaging and separation, offering insights into its importance and future trends.

What You Will Learn

- Understanding Food Waste Depackaging: Learn how removing packaging materials improves recycling and composting efforts.

- Key Benefits of Effective Food Waste Management: Discover how it reduces landfill waste, conserves resources, and minimizes greenhouse gas emissions.

- Operational Steps of Depackaging Machines: Gain insights into the loading, transporting, and shredding processes essential for efficiency.

- Separation Techniques: Explore various methods like mechanical sorting and ballistic separators that enhance material recovery.

- Innovations in Waste Management: Stay updated on new technologies like advanced sensors and automated systems transforming food waste separation.

- Choosing the Right Equipment: Understand the critical factors to consider when selecting depackaging machinery for your specific needs.

- Championing Sustainability: Learn how aligning business strategies with environmental goals can lead to lasting benefits and community involvement.

- Call to Action: Discover steps every individual and business can take to promote sustainable waste management practices.

Understanding Food Waste Depackaging and Separation Equipment

Defining Food Waste Depackaging and Separation Technology

Food waste depackaging refers to the process of removing packaging materials from food waste before it is processed. This technology is essential for recycling and composting efforts. It helps ensure that the organic materials are clean and free of contaminants, making them more useful for various applications.

The Importance of Managing Food Waste Effectively

Managing food waste is crucial for several reasons:

- Reduces the amount of waste sent to landfills.

- Helps in conserving natural resources.

- Minimizes greenhouse gas emissions from decomposing waste.

By implementing food waste management strategies, businesses can not only improve their sustainability efforts but also enhance their brand image.

How Food Waste Depackaging Machines Operate

Step-by-Step Process of Food Waste Depackaging

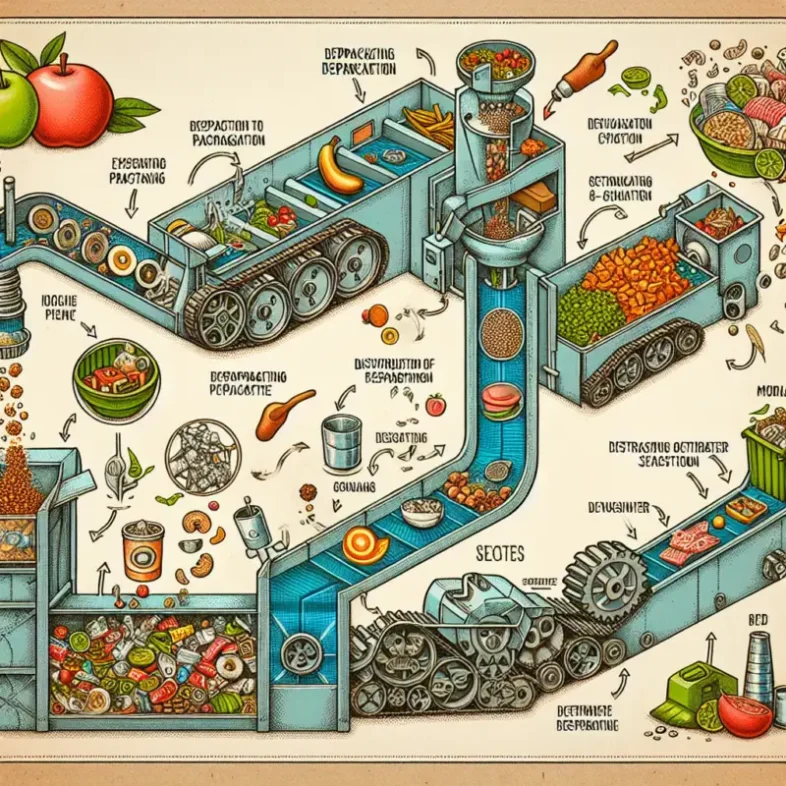

The operation of food waste depackaging machines can be broken down into several steps:

- Loading: Waste is loaded onto the machine.

- Transporting: Conveyor belts move the waste through the system.

- Shredding: Packaging is shredded to facilitate separation.

These steps ensure that the waste is processed efficiently, making the separation process smoother.

Loading and Transporting Waste via Conveyor Belts

Conveyor belts play an essential role in the depackaging process. They help in:

- Efficiently moving waste to the shredding area.

- Reducing manual handling, which can be labor-intensive.

- Maintaining a steady flow of materials for processing.

The Role of Shredding in Depackaging

Shredding is a vital step in the depackaging process. It helps to:

- Break down packaging materials into smaller pieces.

- Prepare the waste for effective separation.

- Increase surface area for better processing.

Overall, shredding significantly aids in the efficiency of the entire system.

Separation Techniques: The Heart of Efficiency

Separation techniques are fundamental to ensuring that materials are effectively sorted. Some common methods include:

- Mechanical sorting

- Air-based separation

- Manual sorting

Each of these methods contributes to maximizing the quality of the separated materials.

Understanding Mechanical Sorting: Trommel Screens Explained

Trommel screens are a popular mechanical sorting method. They work by:

- Using rotating cylindrical drums to sift materials.

- Allowing smaller particles to pass through while larger items are separated.

- Enhancing the overall efficiency of the sorting process.

Ballistic Separators: Advanced Material Separation

Ballistic separators utilize a unique design to achieve advanced material separation. Key features include:

- Using air and vibration to sort materials based on weight and shape.

- Improving the recovery rate of valuable materials.

- Reducing contamination of the separated materials.

Benefits of Food Waste Depackaging and Separation Equipment

Enhancing Recycling Efforts Through Effective Separation

Effective separation of food waste leads to better recycling outcomes. This technology helps:

- Ensure high-quality materials for recycling.

- Reduce contamination in recyclable streams.

- Improve the overall efficiency of waste management systems.

Contributing to Renewable Energy Initiatives

Food waste depackaging can significantly support renewable energy efforts. By diverting organic waste from landfills, we can:

- Produce biogas through anaerobic digestion.

- Generate nutrient-rich compost for agriculture.

- Help decrease reliance on fossil fuels.

Future Trends in Food Waste Management Technology

Innovations on the Horizon for Waste Treatment

As we look ahead, the world of food waste management is poised for some exciting changes. Companies are investing in new technologies that aim to make the process of waste treatment more efficient and effective. Some of the key innovations include:

- Advanced sensor technology for better sorting.

- Biodegradable packaging options to reduce waste.

- Smart waste management systems that use data analytics.

The Role of Automation in How Food Waste Depackaging and Separation Equipment works

Automation is changing the landscape of food waste separation. By incorporating automated systems, businesses can streamline their processes and improve accuracy. Here are some ways automation is making a difference:

- Robotic arms for precise sorting of materials.

- Automated monitoring systems for real-time data.

- Self-operating machinery that reduces labor costs.

Choosing the Right Equipment for Your Business Needs

Factors to Consider When Selecting Depackaging Machinery

When it comes to selecting the right depackaging machinery, several important factors must be taken into account. Understanding these factors will help ensure that the equipment meets the specific needs of your operation. Consideration should include:

- The volume of food waste generated.

- Types of materials being processed.

- Budget constraints and cost-effectiveness.

Matching Equipment Features to Business Scale and Operations

Not all businesses are the same, and neither are their waste management needs. It’s essential to match equipment features to your specific scale and operations. Key features to evaluate include:

- Capacity and throughput rates.

- Ease of maintenance and operation.

- Integration capabilities with existing systems.

Championing Sustainable Practices with Food Waste Management

Aligning Business Strategies with Environmental Goals

In today’s world, aligning business strategies with environmental goals has become crucial. Companies are recognizing that sustainable practices can lead to long-term benefits. Some effective strategies include:

- Implementing energy-efficient systems.

- Engaging in community food recovery programs.

- Educating employees about waste reduction.

Community Involvement and Educational Initiatives

Community involvement is a vital aspect of effective food waste management. By participating in local initiatives, businesses can foster a culture of sustainability. Examples of initiatives include:

- Workshops on composting and recycling.

- Partnerships with local food banks.

- Volunteering at community clean-up events.

Encouraging a Sustainable Future Through Effective Waste Treatment

Call to Action for Businesses and Consumers Alike

Every individual and business has a role to play in promoting a sustainable future. It's essential to take action, both on organizational and personal levels. Here are some steps to consider:

- Invest in sustainable waste management solutions.

- Educate others about reducing food waste.

- Advocate for policies supporting waste reduction.

How Food Waste Depackaging and Separation Equipment Works – Step by Sep

In the depackaging equipment of the past the first step in the process involves disposing of food waste into the equipment. Most models can handle various types of packaged waste, including cans, plastic bottles, tetra pack containers, and bags. The process begins by loading the waste onto a conveyor belt or augur that transports the material to a shredding component.

Shredding

The shredder uses rotating parts with sharp edges to tear apart the packaging material and expose the organic content inside. Some models may have various shredding settings to handle different types of materials, from soft plastics to hard metals.

Separation

In the older machines, after shredding, the mixture of packaging material and organic content moves on to a separation stage. This is where things get interesting: A combination of mechanical sorting techniques like trommel screens or, if the item sizes are large enough were until recently used, for example ballistic separators might be used at this stage.

Trommel screens have been used for separation of mixed waste fractions for many years. They are are large cylindrical frames that rotate. They have holes that allow smaller pieces (the organic matter) to fall through while larger items (the packaging) remain inside the drum.

On the other hand, ballistic separators use AI computer systems to identify recyclable materials and use air-jets or paddles that move the rejected material items from the depackager in a certain way so that they separate materials based on their size and weight. For example lighter items (packaging) are moved upward while heavier items (metal objects etc.) slide downward.

After Separation

Once separated, both streams of materials – organics and non-organics – are then further processed separately. The organic material can be composted or anaerobically digested to create fertilizers or biogas, contributing towards renewable energy initiatives. On the other hand, non-organic components can be recycled if they meet certain criteria; otherwise, they would be disposed of according to local regulations.

You may also like to read:

Final Thoughts on the Importance of Responsible Waste Management in Food Waste Depackaging and Separation Equipment works

Responsible waste management is crucial for the health of our planet and communities. By adopting better practices and technologies, we can all contribute to a cleaner, greener future. Let's work together to make a real difference!

In conclusion, food waste depackaging and separation equipment offer a sustainable solution to manage food waste effectively. By separating organic matter from its packaging, these machines allow for efficient recycling and energy production processes. As technology advances, we can expect more efficient models that will further enhance the waste management process in the food industry.

The Future of Recycling: The Importance of Food Waste Depackaging and Separation Equipment

The future of recycling is a topic that has garnered significant attention in recent years. As the world's population continues to grow, so does the volume of waste that we produce. This waste, if not managed properly, can have devastating effects on our environment. One area where this issue is particularly pertinent is food waste. […]

How to Choose the Right Food Waste Depackaging and Separation Equipment for Your Business

Whether you own a small-scale business or a large-scale industry, waste management is a crucial factor that can significantly impact your operations and environmental footprint. One essential part of this process is dealing with food waste through depackaging and separation. As such, choosing the right food waste depackaging and separation equipment for your business is […]

The Role of Food Waste Depackaging and Separation Equipment in Sustainable Waste Management

In recent years, the issue of waste management has become critical due to urbanization and population growth. One aspect that requires significant attention is food waste, a major contributor to overall waste production. With the growing awareness about sustainability and resource conservation, managing food waste has become crucial. In this regard, food waste depackaging and […]

Understanding the Basics of Food Waste Depackaging and Separation Equipment

Depackaging and separation equipment is a fundamental aspect of managing food waste, a growing concern worldwide due to its environmental implications. This equipment is used to separate packaging materials from organic content, ensuring that the maximum amount of waste can be recycled or converted into useful products. Food waste depackaging and separation equipment is typically […]